Clever Ideas: UL Label Kits

I recently worked with a client who needed multiple UL labels to properly mark a product his company built on a production line. He admitted he was in a rush because they had forgotten to reorder one of the labels, and they were now nearly out. After helping him with his immediate need, I circled back a began discussing how he might solve the inventory management issue. The solution: UL Label Kits

Instead of thinking on an individual label per label basis, I challenged him to considered the labels as a complete system. They were after all being used on the same device.

We ended up designing a product where all the labels were nested together on one sheet. Suddenly he was managing one sheet of labels in inventory instead of 5 different. But even more than that, a happy benefit was that his production staff was managing one sheet instead of five. Why do I mention that, because they found their error rate due to mislabeled products dropped after the change. With one sheet per device, it became very clear when a label hadn’t yet been applied.

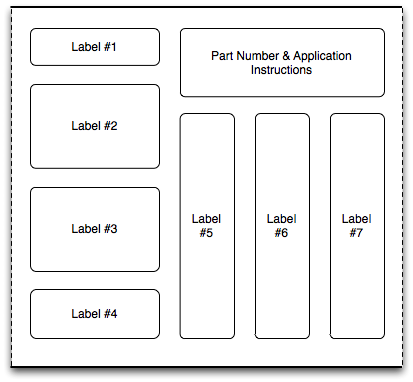

Consider the example image I’ve created below. Rather than issuing seven rolls of material, everything is combined onto one perforated section. The bill of materials is easier to parse, and the production floor has fewer loose articles to utilize and manage.

Do you have a label application process or bill of materials that involves multiple labels? You may want to consider utilizing custom designed label kits. Nesting labels is one of the easiest ways to make your process just that much more efficient. Some additional benefits of kits include:

Poka-yoke (ポカヨケ) – Japanese lean Label Kit manufacturing term for mistake-proofing the manufacturing process

• If any label is still on the sheet, a labeling opportunity has been missed

• Relevant instructions can be include on the label sheet

The simultaneous printing of all the labels has multiple advantages

• Unparalleled color uniformity between labels

• Material consistency

• Same adhesive freshness for all labels applied to a finished

assembly

Potential cost savings

• Everything—is printed in one efficient pass instead of separately with individual set-up costs