UL Recognized Core Labels

“Make sure you have your core labels,” says pretty much every UL Inspector ever.

One of the biggest reasons UL 969 labels are rejected by a UL Inspector is the lack of core labels. But what exactly are core labels, and why are they so important? Let’s start with the why. Let me walk you through this this logical progression:

- UL 969 labels are considered Recognized Components

- Recognized Component are essentially verified pieces (or ingredients as it were) that are used to make up a final end-product

- When a product is receiving final approval from a UL inspector, they need to know that everything meets the various required specifications

- Since a Recognized Component isn’t made in the end-product facility, the only way to verify it meets the required specifications is some sort of marking

- For the UL 969, that marking is usually a special label stuck on the inside core of the product

- If there is no core label, the UL inspector can’t verify that the labels meet the end-products requirements

- If the UL inspector can’t verify that the labels meet the end-products requirements, the product doesn’t ship

Yikes! Did a shipment of product just get delayed because of a core label? Yes. I cannot tell you how many times some purchaser has called me up in a panic because the company they bought labels from last time didn’t include the proper markings. The core labels are essentially for proving that the UL 969 compliant labels are what they purport to be.

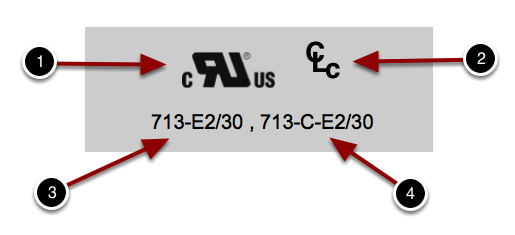

Now that we know that we absolutely need these core labels, what should you be looking for? Thankfully they aren’t overly complex. The key is to correctly conveying the required information. Take a look a the visual break down below:

- Recognized Component Mark. In this particular case, this mark signifies the compliance in both the USA and Canada (UL 969 and CSA C22.2 No. 0.15 standards respectively).

- This is manufacturer’s brand–basically the same concept as cattle. In this case I’m using a marking from Coast Label Company. In lieu of a brand, a company’s name can also be used in this location.

- This is the recognized component’s US part number. This let’s the inspector know exactly what the conditions of acceptability are for the product. You can find part number by searching Coast Label’s PGDQ2 file.

- As this particular construction is approved for the US and Canada, it has a Canadian part number as well. You can find it in Coast Label’s PGDQ8 file.

Once placed on the inside core of a role of labels, the UL inspector can verify the product. No more delayed shipments, and one happy compliance team. It just takes a company or project engineer who knows what they are doing and has good control of the project and manufacturing process.